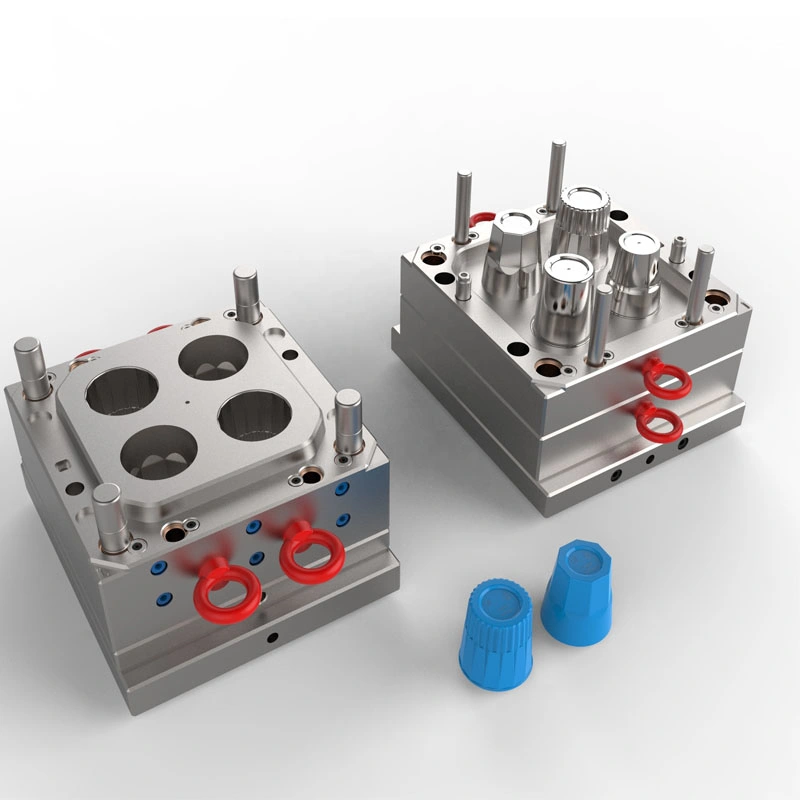

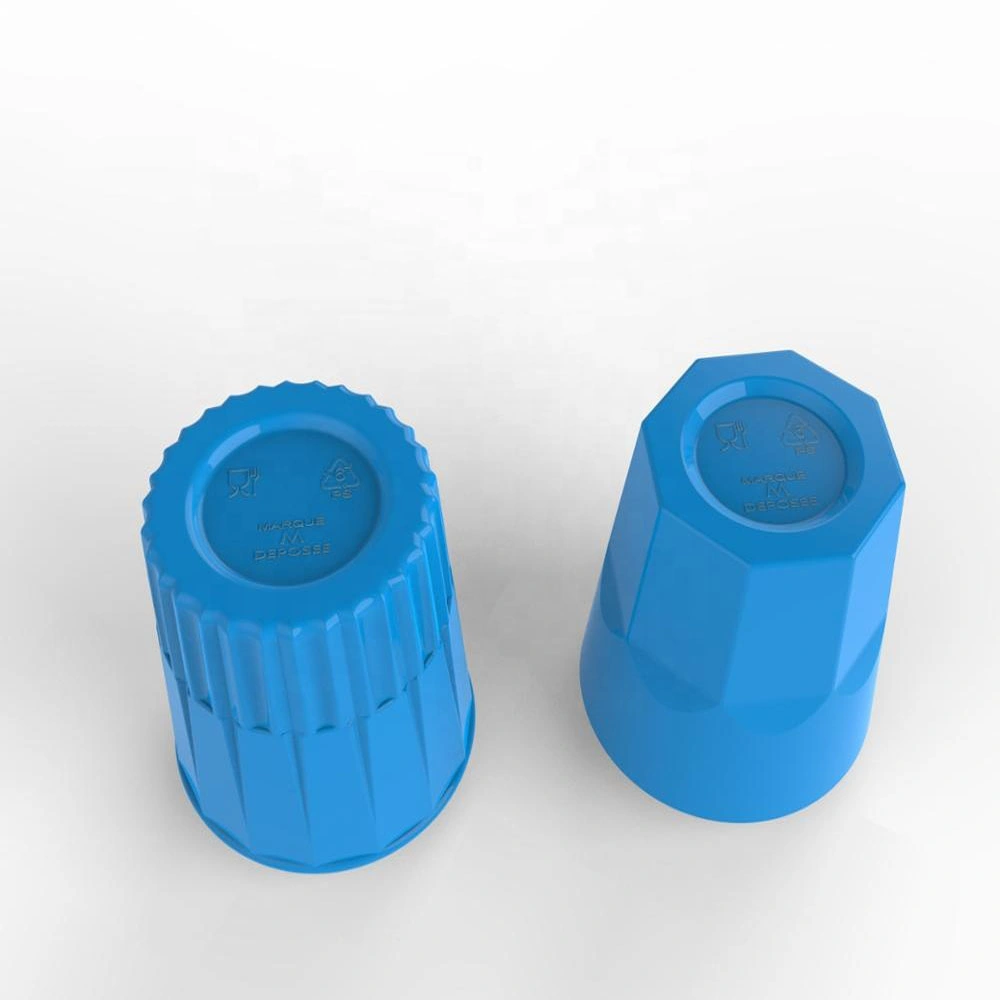

Manufacturing Tea Cup Coffee Cup Thin Wall Mould PP Plastic Injection Mold

Package Size 100.00cm * 100.00cm * 100.00cm Package Gross Weight 30.000kg Products Description Why Choose Us 1. We has r

Description

Basic Info.

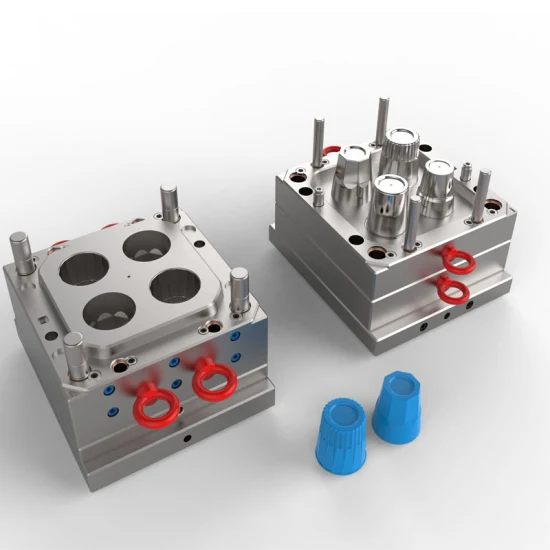

| Model NO. | OKEMOLD-2023-0246 |

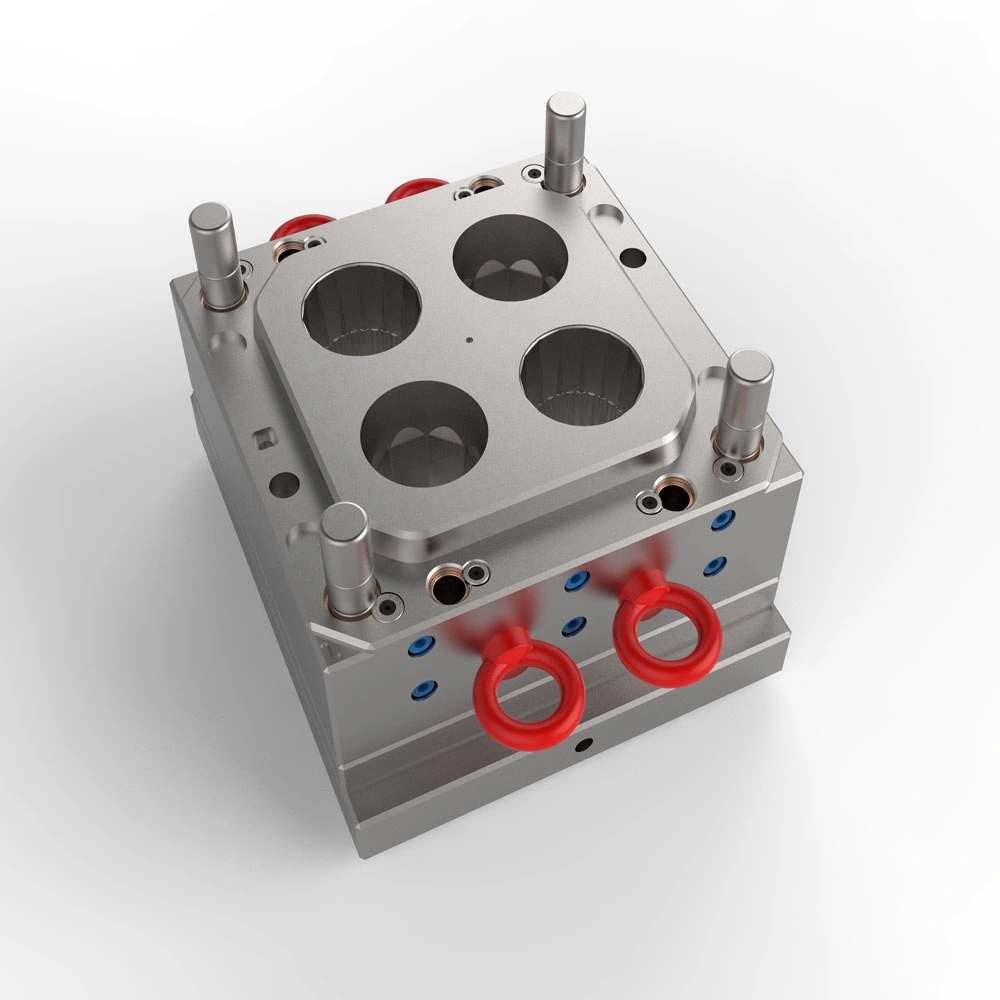

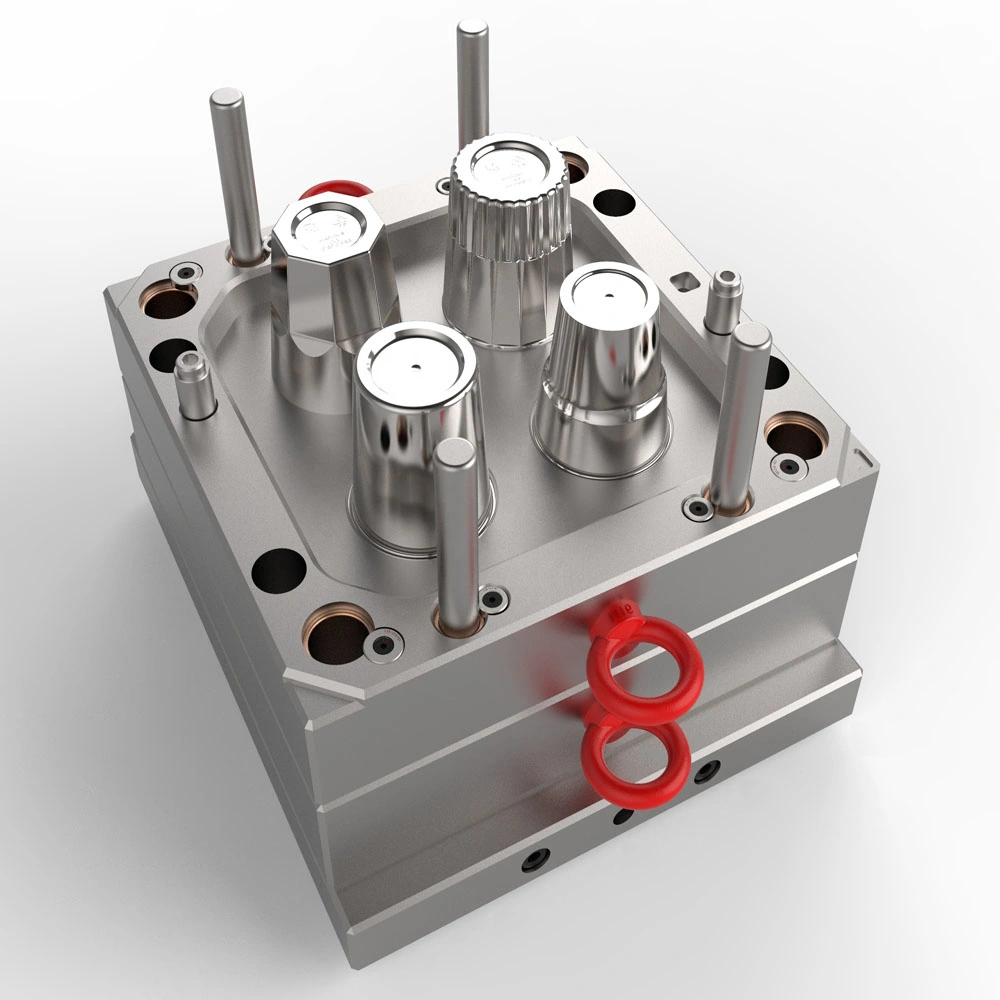

| Mould Cavity | Multi Cavity |

| Plastic Material | PP |

| Process Combination Type | Injection Mode |

| Application | Commodity, Home Use |

| Runner | Hot Runner |

| Design Software | AutoCAD |

| Installation | Mobile |

| Certification | ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 1year |

| Mold 3D Type | STP/Step/X-T/Igs |

| Mold Mould Life | 500000-3000000 Shots |

| Mold Leading Time | 45s T1 After Confirmation |

| Mold Spares | Free |

| Mold Test Video | > 5 Min |

| Mold Material | H13/P20/718/2314 |

| Mold Cavity | 4 Cavities |

| Mold Usage | Injection Tools |

| Transport Package | Wooden Box |

| Specification | 100cmx100cmx100cm |

| Trademark | OKEMOLD |

| Origin | China Zhejiang |

| HS Code | 8480719090 |

| Production Capacity | 2000 Stes / Year |

Packaging & Delivery

Package Size 100.00cm * 100.00cm * 100.00cm Package Gross Weight 30.000kgProduct Description

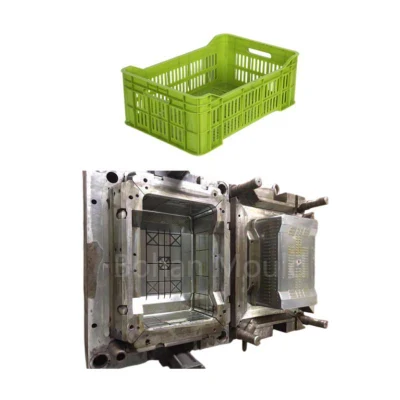

| Cup Mould |

| Many kinds of Cup Mold for you to choose to make |

| Mold Name | Manufacturing Tea Cup Coffee Cup Thin Wall Mould PP Plastic Injection Mold |

| Mold Material | P20 / 718 / 2738 / H13 / S136 / NAK80 |

| Material Hardness | HRC28 - HRC60 |

| Material Treatment | Quenching / Nitrided / Heat |

| Mold Surface | Texture / Mirror polish / Customizable |

| Mold Surface | DME / LKM / HASCO / LOCAL |

| Products Material | PP / PE / PA / PS / PC / ABS / TPE / PET / PMMA/PET |

| Delivery Time | Less than 45 days after mold design confirmed |

| Cup Mould Feature | Mold Steel: H13 | Mold Runner:Hot | Raw Material: PP |

| Mold Gate: Pin | Ejection system: Ejector Plate | Injection molding |

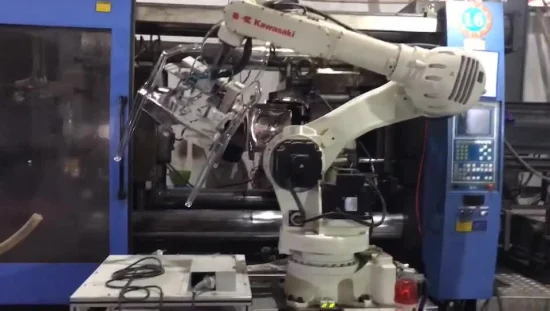

Recommend ProductsCampany Profile

| Corporate vision: |

| Realistic, innovative, create a first-class enterprise, create international top products, achievement of a positive life. |

| Management philosophy: |

| Standardization, data, bit by bit improvement, never stop. |

| Business strategy: |

| Quality brand, leading technology, efficient operation, create core competitiveness. |

| Quality policy: |

| Quality first, timely delivery, so that customers are more satisfied. |

Exhibition

FAQ

Q1. When can I get the price?A: We usually quote within 2 days after we get your inquiry. If you are very urgent, please call us or tell us in your email so that we will regard your inquiry priority. Q2. How long is the lead-time for mold?A: It all depends on the mold's size and complexity. Normally, the lead time is 15-45days.

If the molds are very simple and not big size, we can work out within 15 days.Q3. I have no 3D drawing, how should I start the new project?

A: You can supply us a sample, we will help you finish the 3D drawing design.Q4. Before shipment, how to make sure the products quality?

A:If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker. We will supply you a video for production process detail include process report, products size ,structure and surface detail, packing detail and so on.

Q5.Can you do post production?

A: Some customers in addition to plastic injection require post processing, assembly of their products and packaging. We have done this numerous times and have the facility and staff ready for these processes. You are welcome to inquire about post production if you need it. Or send us a quote request for any part you need. We will be happy to assist you with the quote or any technical, packaging, post processing or shipping inquiry.

Our Contact

Send now