PS Thin Wall Plastic Cutlery Mould Injection Mould

Description

Basic Info.

| Model NO. | KLTM05 |

| Application | Household Appliances, Furniture, Commodity, Home Use, Transportation |

| Runner | Hot Runner/Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | CE, ISO |

| Standard | DME |

| Customized | Customized |

| After-sales Service | Technical Guidance |

| Hardness | 45-48HRC |

| Injection Gate | Edge Gate |

| Processing | High Precision Tooling Machine |

| Mould Name | Plastic Fork Spoon Mould |

| Transport Package | Wooden Case |

| Specification | Customized |

| Trademark | Kelong Mould |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 800sets/Years |

Product Description

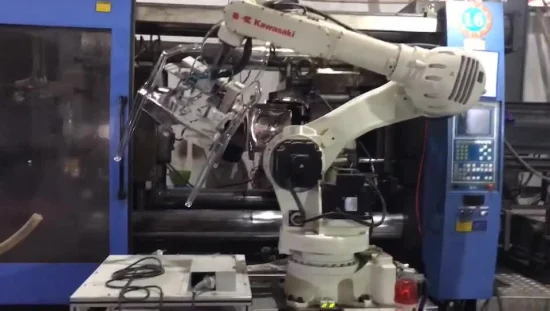

Disposable plastic spoon fork and knife mould is the Fast food suppliers' key to open the door of large molding business profit. Large production capacity for PS spoon and fork , PP spoon and fork knife mould at a high speed thinwall production line.

KELONG Mould offer plastic cutlery mould such as 32cavity, 64cavity and stacking 48+48cavity for plastic spoon moulds, plastic knife mould, plastic fork mould can run with cycle time of 5seconds. And plastic tray mould, thinwall plastic containers 500ml and disposable 1L box mould in 3seconds cycle time in four cavity.

The solution of high speed container and plastic cutlery mould is not only because the good steel S136 imported from Europe, hot runner system, valve gate system for each key point of thinwall cutlery, but also a reasonable design in the container and plastic spoon, plastic knife and fork design.

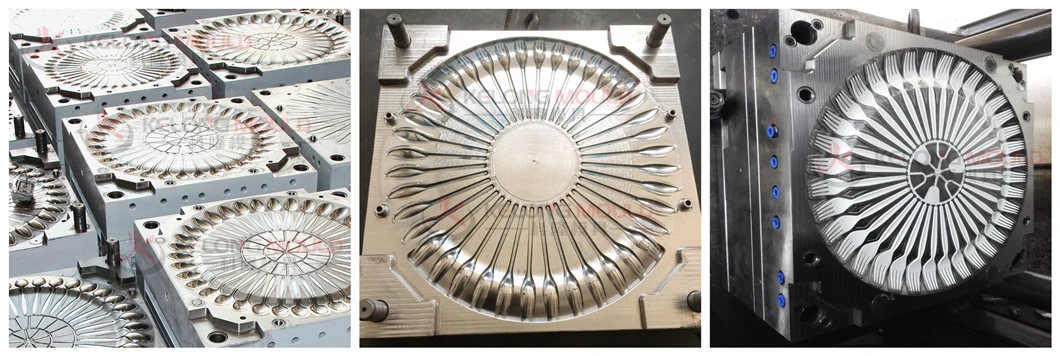

Mould name: Plastic Cutlery Mould Product size: 450*330*210mm

Number of cavities: 48cavities

Die steel material: S136H

Mould size: 750*550*600mm

Suitable for injection moulding machine: 450T

Hot runner: 48 tips hot runner

Ejection system: Ejector pin

Mould cycle time: 6S

Mould life: Three million

Mould lead time: 40-55 days

1. Q: Where is your company or factory?

A: We are located in Zhejiang, Taizhou, We have our own factory.

2. Q: Can you make design?

A: We'll be glad to make designs for you, both product and mould, and for free.

Complete product 2D & 3D and mould 2D & 3D will supply to clients after order.

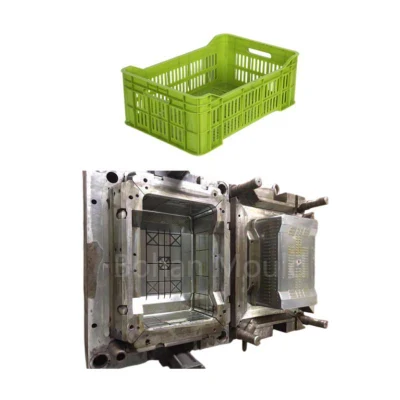

3. Q: What type of mould you can make?

A: We can make all kinds of plastic injection mould, especially rich Experience

on household moulds.

4. Q: What type of files can you accept?

A: We can accept different types of files such as DXF, DWG, IGS, IGES, STP, PRT, X_T, PDF.

5. Q: What type of steel do you use?

A: P20, P20 (H), 718, 718 (H), 2738, 2738 (H), H13, NAK80,2344, S136, 4Cr13, S55C,C45#

6. Q: What kind of material you use for test mould and production?

A:PP, PC, PS, PE, HDPE, POM, PA6, PA66, PA6+GF, ABS, TPU, TPE, PVC, SMC, BMC,

We have rich experience for manufacturing product with these materials and know

how to adjust Parameter to get the perfect product.

7. Q: How to send sample?

A: The quotation we offer you including The cost of sample delivery 2 times samples by

DHL, UPS, EMS,FEDEX or TNT.

Our Contact